Enzymatic Degumming

Objective: Our Enzymatic Degumming process is designed to efficiently remove hydratable phospholipids and impurities from crude oil. By utilizing the unique properties of hydratable phospholipids, we achieve superior degumming results, ensuring the production of high-quality refined oil.

Key Process Details:

- Unique Phenomenon:

- Enzymatic Degumming capitalizes on the property of hydratable phospholipids, which have polar groups that form liquid crystals in the presence of water.

- These polar groups create a laminar structure that is insoluble in oil and has the ability to absorb other impurities.

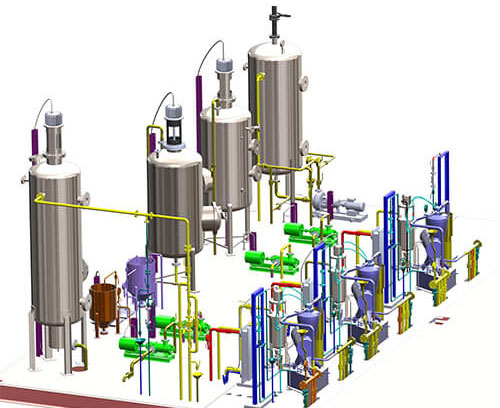

- Efficient Degumming Process:

- Crude oil is continuously and consistently pumped through a dedicated pump.

- It is then heated to the required temperature in a heat exchanger.

- In a specially designed Retention Tank, the heated oil is mixed with a pre-calculated quantity of Phosphoric Acid+ Enzyme+ water Mixture.

- The Enzyme reacts with the crude oil in the Retention Tank, providing sufficient residence time for degumming.

- The mixture of hydrated gums and oil is effectively separated in a Centrifugal Separator.

Description

Our Approach:

- We are a leading manufacturer, supplier, and exporter of Enzymatic Degumming solutions.

- Our focus is on providing cost-effective and efficient degumming processes.

- We offer turnkey projects for complete Enzymatic Degumming, including equipment design, installation, and commissioning.

In summary, our Enzymatic Degumming process utilizes the unique properties of hydratable phospholipids to efficiently remove impurities from crude oil, ensuring the production of high-quality refined oil.

Our Enzymatic Degumming process efficiently removes impurities from crude oil by harnessing the properties of hydratable phospholipids. Choose us for cost-effective and high-quality degumming solutions.

There are no reviews yet.