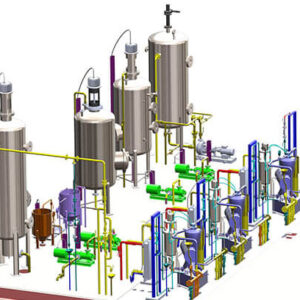

Objective: Our Hydrogenation Plants are designed to enhance the quality and functionality of various oils through the hydrogenation process. This technology involves the controlled addition of hydrogen gas in the presence of a catalyst, resulting in improved oil properties suitable for various applications.

Key Process Details:

- Hydrogenation Process:

- Deodorized oil is heated in an autoclave to approximately 160°C.

- Hydrogen gas is introduced into the oil with the presence of Nickel (Ni) as a catalyst.

- The hydrogenation process continues until the desired quality of Vanaspati (hydrogenated vegetable ghee) is achieved.

- Once the gassing cycle is complete, the supply of hydrogen gas is released from the autoclave.

- Cooling and Filtration:

- The hydrogenated oil is cooled under vacuum conditions and transferred to a cooler drop tank for further cooling.

- The oil mass is then filtered using Plate & Frame filters to remove impurities, resulting in filtered Vanaspati.

- Post-Treatment:

- Following hydrogenation, the Vanaspati oil undergoes post-treatment processes such as post-bleaching to improve color and deodorization to reduce inherent odors.

- Different permitted oils may be blended with the hydrogenated oil in allowable quantities to achieve specific product characteristics.

- Cooling and Storage:

- After the deodorization process, the oil is cooled and sent for packing.

- It is then stored in a cold room for 24 hours to allow the Vanaspati to set and form grains.

Features of Hydrogenation Plants:

- Long Service Life

- Rugged Design

- High Operational Fluency

Reviews

There are no reviews yet.